The Heavy Vehicle Access Upgrade Project is a milestone effort to enhance road safety, improve accessibility, and strengthen local connectivity, specifically within the Cheetham Salt Facility. This collaborative undertaking by the Federal government and Light Regional Council is supported financially by the Heavy Vehicle Safety and Productivity Program.

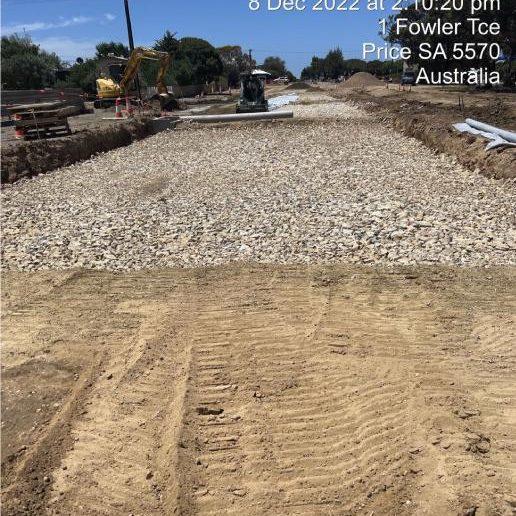

Our core objective is to deliver an unrivaled level of service, accommodating designated freight and commuting traffic throughout the region. This initiative includes the reconstruction of a 2.2km roadway spanning Gardner Street and Fowler Terrace, alongside a major intersection upgrade at Gardner St & Fowler Terrace to accommodate heavy vehicle turning movements.

Jakelco Contracting successfully completed the project within the stipulated six-month timeline, earning commendation from the council for our performance